In the high-stakes environment of complex chemical processing, the ability to distinguish and quantify components like ethanol and methanol in real-time is often the deciding factor between a strictly controlled reaction and an off-spec batch. Traditionally, operators have relied on manual extraction for laboratory analysis. However, this method introduces significant delays and safety risks that […]

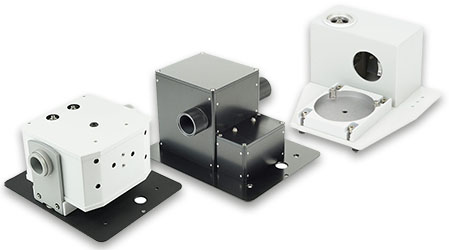

FlexiSpec®

FlexiRay®

FlexiService

Moving Beyond the Bench: In-Line FTIR Monitoring with ATR Probes For decades, Attenuated Total Reflection (ATR) has been a standard technique for FTIR spectroscopy. However, most users are restricted to standard ATR inserts or benchtop accessories. While effective for static lab samples, these setups introduce a critical bottleneck: the sample must be extracted from the […]

art photonics GmbH is pleased to announce our participation as an exhibitor at PAT Connect 2026, taking place this March at the TTC Technology Training Center. As industries increasingly shift toward real-time monitoring and automation, Process Analytical Technology (PAT) is more critical than ever. Taking the Spectrometer to the Sample Whether you are scaling up […]

The art photonics GmbH team has arrived in California and is pleased to be back at the Moscone Center for the start of SPIE Photonics West 2026. Our delegation - led by CEO Dr. Stefanie Foerster, alongside Sales Manager Marco Antonio Ferreira Cipriano and Product Line Manager Joachim Gerike - is on-site and prepared for […]