art photonics is looking for a Senior Product Line Manager to join our team in Berlin. As a key member of our company, you will: You should have a proven track record in technical product management and be fluent in both German and English. If this sounds like the right challenge for you, we invite […]

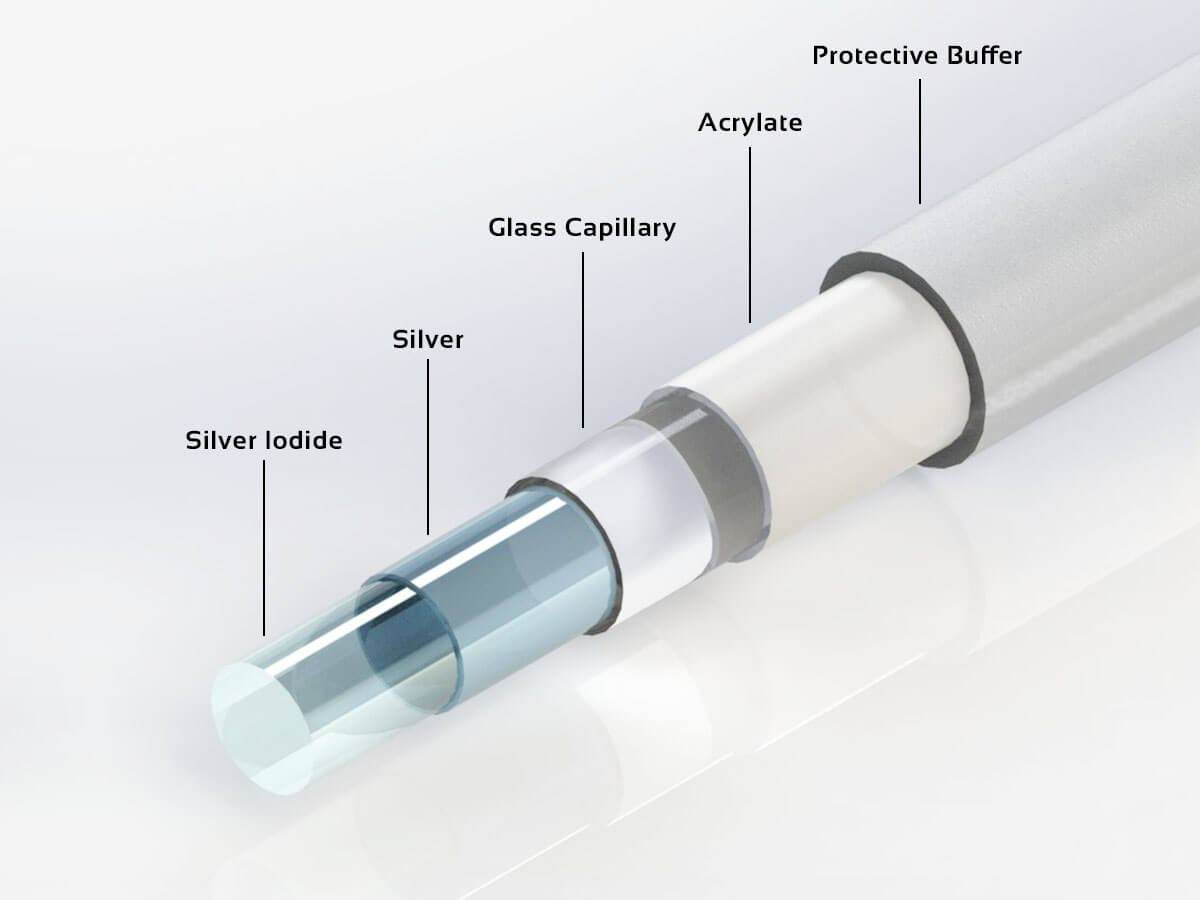

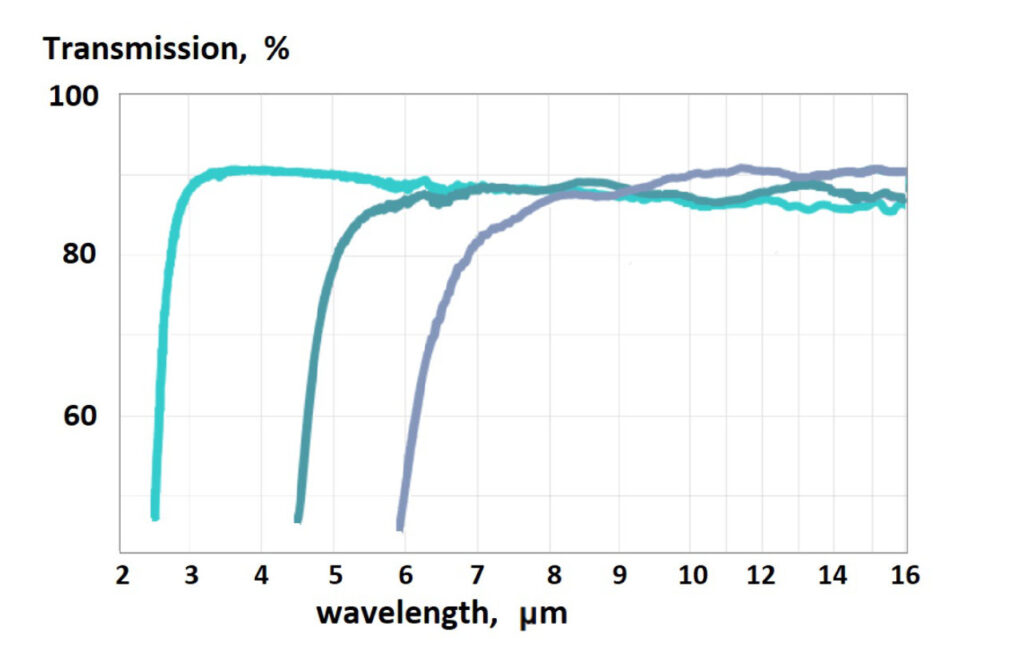

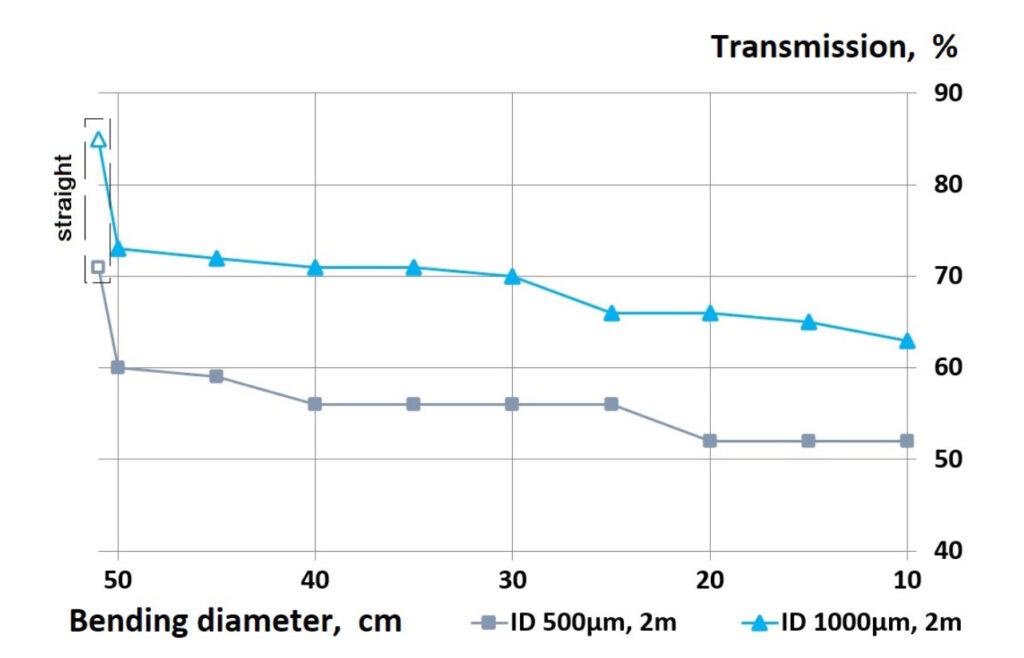

FlexiSpec®

FlexiRay®

FlexiService

Summer Sale – special prices for a limited time! art photonics GmbH invites researchers, process engineers, and OEM developers to take advantage of our exclusive summer promotion. For a short period, selected specialty fiber-optic products are available from stock at substantially reduced prices. What is included: Important: stock is limited and products will be supplied […]

Are you facing challenges in obtaining reliable chemical information during process monitoring? Our latest multi-modal fiber optic probe delivers data from ATR, Transflection, and Raman spectroscopy at the same measurement point**, giving you a fuller picture in real time. During CSI XLIV in Ulm, art photonics will present this technology in detail. Dr. Viacheslav Artyushenko, […]

LASER World of PHOTONICS 2025 has officially commenced, and art photonics GmbH is excited to participate in one of the world's leading photonics events in Munich. Visit the Nynomic AG Group at Booth A3.218! We are proudly exhibiting as part of the Nynomic family, alongside our esteemed partners including NLIR, Avantes, and other leading companies […]