Summer Sale – special prices for a limited time! art photonics GmbH invites researchers, process engineers, and OEM developers to take advantage of our exclusive summer promotion. For a short period, selected specialty fiber-optic products are available from stock at substantially reduced prices. What is included: Important: stock is limited and products will be supplied […]

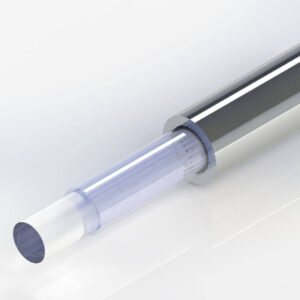

FlexiSpec®

FlexiRay®

FlexiService

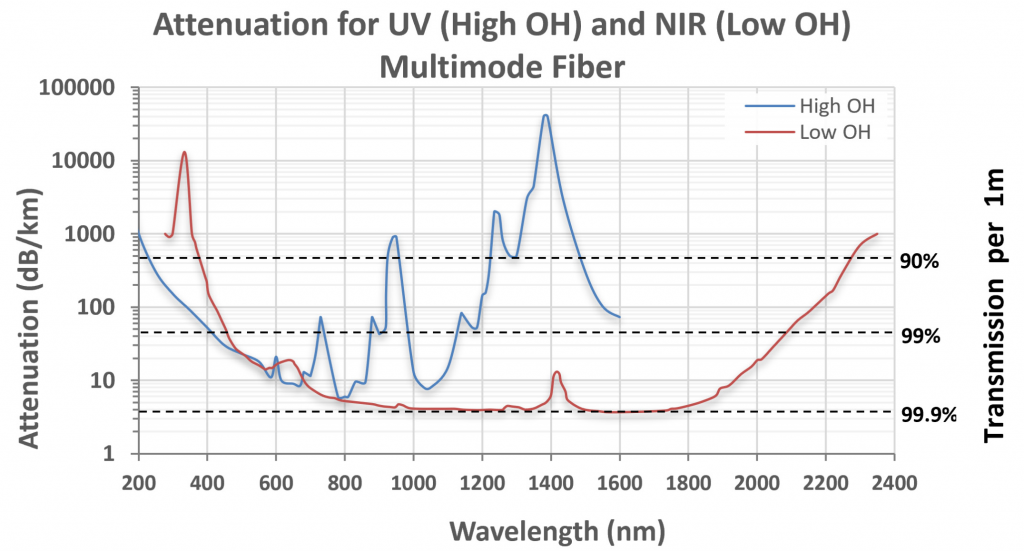

Ever wondered how you can monitor wine fermentation in real time without disturbing the process? In our latest application note at art photonics, we explain how the combination of mid-infrared (mid-ir) and uv-vis spectroscopy with fiber-based technology is transforming fermentation analysis. Our study on Federweißer (fresh wine) revealed that key ethanol peaks become clearly visible […]

LASER World of PHOTONICS 2025 has officially commenced, and art photonics GmbH is excited to participate in one of the world's leading photonics events in Munich. Visit the Nynomic AG Group at Booth A3.218! We are proudly exhibiting as part of the Nynomic family, alongside our esteemed partners including NLIR, Avantes, and other leading companies […]

art photonics is pleased to announce that our R&D Manager, Alexander Novikov, will be presenting at the Biophotonics and Medical Applications Forum at Laser World of Photonics 2025. In his session, "Laser technologies in healthcare: Advances and applications," Alexander will share how our novel fiber optics probes are paving the way for real-time, non-invasive analysis […]