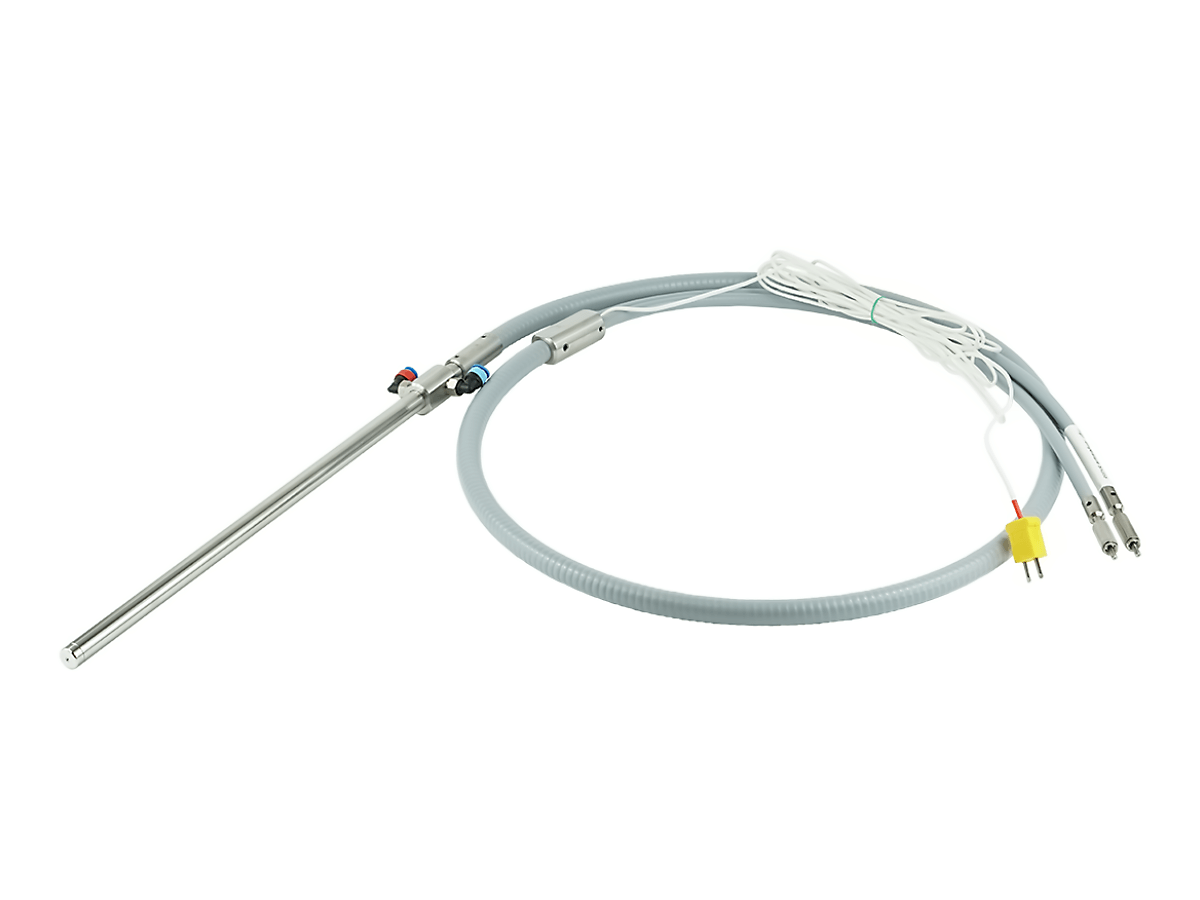

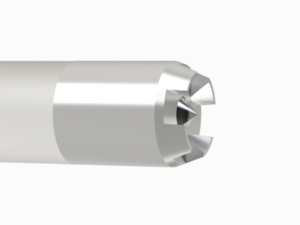

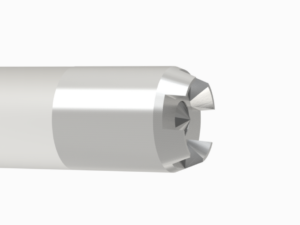

Unlock remote gas analysis with art photonics' innovative Transflection Fiber Probe. Are you facing challenges with real-time gas measurements in process control or PAT? Our Transflection Fiber Probe is engineered for remote spectroscopy and seamless in-line process control. What is Transflection?This technique effectively doubles the light's journey through your gas sample, which significantly increases detection […]

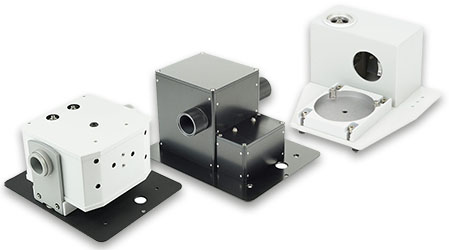

FlexiSpec®

FlexiRay®

FlexiService

Happy International Day of Light! Today, art photonics is proud to shine a light on the incredible versatility of illumination and the advanced technologies that harness its power. We continue to drive progress across various fields with our comprehensive range of specialty optical fibers. Our innovative solutions span an exceptionally wide spectral range - from […]

LASER World of PHOTONICS 2025 has officially commenced, and art photonics GmbH is excited to participate in one of the world's leading photonics events in Munich. Visit the Nynomic AG Group at Booth A3.218! We are proudly exhibiting as part of the Nynomic family, alongside our esteemed partners including NLIR, Avantes, and other leading companies […]

art photonics is pleased to announce that our R&D Manager, Alexander Novikov, will be presenting at the Biophotonics and Medical Applications Forum at Laser World of Photonics 2025. In his session, "Laser technologies in healthcare: Advances and applications," Alexander will share how our novel fiber optics probes are paving the way for real-time, non-invasive analysis […]