If you look closely at our holiday card this year, you might notice a familiar tool in an unfamiliar setting. Yes, that is one of our probes in the wine glass! It is a little nod to who we are: even when we are celebrating, we never stop thinking about the science that brings us […]

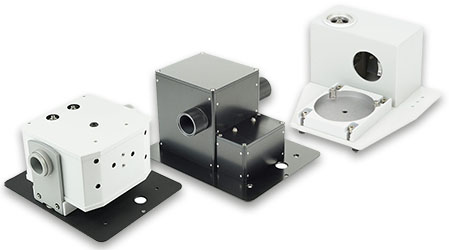

FlexiSpec®

FlexiRay®

FlexiService

Believe it or not, Christmas 2025 is fast approaching. For many, the holiday season is synonymous with traditional markets and the comfort of a hot cup of mulled wine. However, there is a genuine scientific reason why you should never let your Glühwein boil, and it goes beyond simple culinary advice. In our latest Application […]

The art photonics team is currently fully engaged at the 20. Herbstkolloquium Prozessanalytik, and with two days already behind us, we are thrilled with the productive atmosphere and the depth of the technical exchanges. The event kicked off with strong momentum, setting the stage for deep discussions on the future of process control. We were […]

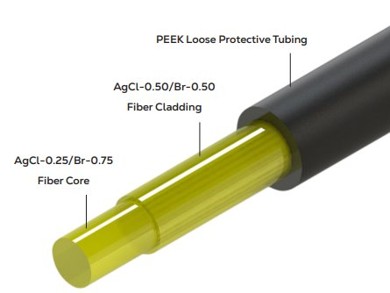

In complex chemical analysis and biomedical diagnostics, relying on a single spectroscopic technique often results in a "blind spot." While Near-Infrared (NIR) offers speed, it frequently lacks specificity. Raman spectroscopy provides a precise molecular fingerprint but often battles fluorescence interference. Mid-IR offers excellent structural detail but is limited by shallow penetration depths. The Challenge: Spatial […]